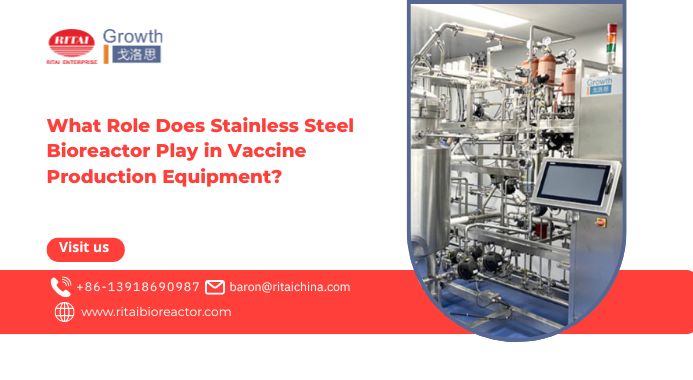

People outside manufacturing often assume vaccine production is driven mainly by biology. Inside a facility, the picture looks different. Biology matters, of course, but it only works as well as the equipment around it allows. One of the most practical decisions in modern vaccine production equipment is the continued use of the stainless steel bioreactor. It’s not a trend, and it’s not about tradition either. It’s about control, predictability, and avoiding unnecessary risk in a process that already carries enough of it.

Why Reactor Material Is Still a Serious Discussion

Vaccine processes don’t leave much room for improvisation. Cell cultures, viral vectors, and recombinant proteins respond quickly to changes in their environment. Small issues—surface residue, inconsistent cleaning, minor contamination—can turn into batch failures.

That’s why material choice still gets so much attention during facility design. Stainless steel remains popular not because it’s perfect, but because its behavior is well understood. Engineers know how it reacts to heat, pressure, cleaning chemicals, and long operating cycles.

That familiarity matters more than novelty in regulated production.

Sterilization Is Where Stainless Steel Earns Its Keep

In vaccine manufacturing, cleaning is not a background task. It’s part of the process.

- Stainless steel bioreactors handle repeated CIP and SIP cycles without changing surface properties or releasing unwanted residues. Over time, this consistency makes validation easier and results more predictable.

- Other materials may work in specific cases, but stainless steel remains the safest option when sterility needs to be repeatable rather than just achievable.

Scale Changes the Conversation

What works in a small development lab doesn’t always behave the same way at production scale. Heat transfer, mixing behavior, and mechanical stress all become more noticeable as volumes increase.

This is where stainless steel reactors fit naturally into large-scale vaccine production equipment. Their structural stability and thermal behavior are predictable, which helps teams scale processes without constantly second-guessing the hardware.

Manufacturers like Ritai Bioreactor focus on these scaling realities, not just nominal vessel volume, when designing production systems.

Surface Quality Has Real Consequences

- Internal finishes aren’t just a specification detail. They affect how easily a reactor cleans, how residues behave, and how consistently batches run over time.

- A properly finished stainless steel bioreactor minimizes product hold-up and makes visual inspection meaningful. These are small things, but in regulated manufacturing, small things add up quickly.

- Facilities that run frequent campaigns or multiple products tend to notice these differences first.

Regulatory Comfort Still Matters

- There’s also a practical, less technical reason stainless steel continues to dominate vaccine manufacturing: regulators are comfortable with it.

- Its performance history is well documented. Inspection criteria are clear. Failure modes are familiar. That reduces friction during audits and requalification.

- For long-term facilities, that predictability often outweighs potential advantages of newer materials.

Flexibility Across Vaccine Platforms

Vaccine technology continues to change, but many facilities need equipment that can adapt without complete replacement.

- A well-designed stainless steel bioreactor can support different cell lines and production strategies with relatively minor modifications. That flexibility makes it easier to respond to shifting demand or new vaccine platforms.

- This is another reason stainless steel remains part of the core infrastructure rather than a legacy choice waiting to be replaced.

A Practical Role, Not a Marketing One

- Stainless steel bioreactors don’t attract much attention when everything runs smoothly. That’s usually a good sign.

- In vaccine production equipment, their role is simple but essential: provide a stable, clean, and predictable environment so biological processes can do what they’re meant to do. Companies like Ritai Bioreactor continue refining these systems because reliability, not novelty, is what production teams rely on.

Closing Thoughts

Vaccine manufacturing doesn’t reward unnecessary experimentation with core equipment. It rewards systems that perform the same way, batch after batch, year after year .The stainless steel bioreactor remains a key part of that reliability. Not because it’s the newest option, but because it consistently supports the demands vaccine production places on equipment. In this field, that consistency is the point.

Leave a Reply