In today’s energy-conscious and regulation-driven environment, electrical efficiency is no longer a technical afterthought—it is a strategic priority. For commercial buildings, industrial facilities, and large residential properties, Power Factor Correction Capacitors in Canada play a pivotal role in maintaining electrical stability, reducing operational risk, and ensuring compliance with national standards.

As utilities impose stricter requirements and energy costs continue to rise, property owners and facility managers must adopt solutions that protect infrastructure while optimising long-term performance. Power factor correction is one such solution—quietly essential, yet profoundly impactful.

Understanding Power Factor Correction Capacitors

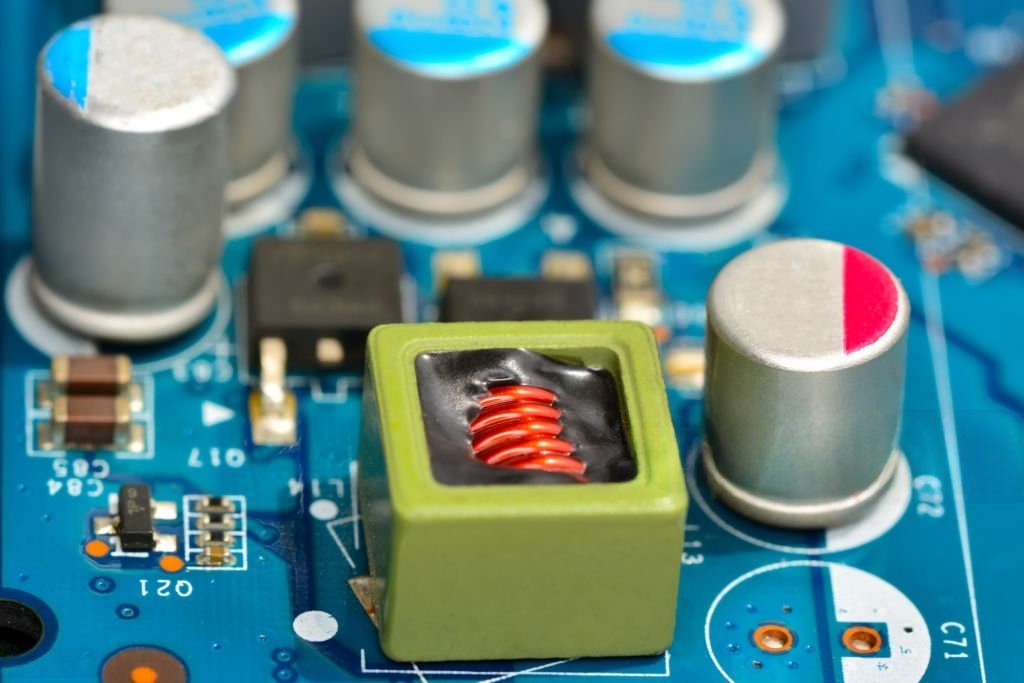

Power factor correction capacitors are designed to offset reactive power within electrical systems. Many modern buildings rely on inductive loads such as motors, HVAC systems, elevators, and industrial machinery. These loads draw reactive power, lowering the overall power factor and placing unnecessary strain on electrical infrastructure.

By installing appropriately rated correction capacitors, properties can stabilise voltage, reduce current demand, and improve overall electrical efficiency. In Canadian installations—where systems often operate under high load and variable climate conditions—this correction is critical for reliability and safety.

Trusted suppliers like en-trade.ca ensure that power factor correction capacitors are engineered to perform consistently within Canada’s regulatory and environmental framework.

Safety Benefits for Property Owners and Occupants

Electrical inefficiency is not merely a cost issue—it is a safety concern. Poor power factor increases current flow, leading to excessive heat in cables, switchgear, and transformers. Over time, this heat accelerates insulation degradation and raises the risk of electrical faults or fire incidents.

High-quality Power Factor Correction Capacitors in Canada support safety by:

- Reducing overheating in electrical conductors

- Minimising voltage fluctuations and instability

- Lowering stress on transformers and distribution equipment

For property owners, this translates into safer electrical rooms, fewer emergency failures, and enhanced protection for occupants and assets alike.

Regulatory Compliance and Utility Requirements

Canadian electrical codes and utility providers increasingly emphasise efficient power usage. Properties operating with low power factor may face penalties, increased tariffs, or mandatory corrective action.

A professional approach to power factor correction supports compliance by:

- Aligning electrical systems with CSA and utility standards

- Providing documented, code-compliant capacitor installations

- Reducing exposure during inspections and insurance assessments

By sourcing compliant components through experienced distributors such as en-trade.ca, property managers can demonstrate due diligence and regulatory alignment with confidence.

Power Factor Correction as a Maintenance Strategy

From a maintenance perspective, power factor correction is a preventive investment. Electrical systems operating under poor power factor conditions experience accelerated wear, higher failure rates, and unpredictable downtime.

Integrating Power Factor Correction Capacitors in Canada into a maintenance strategy helps to:

- Extend the lifespan of motors and transformers

- Reduce nuisance breaker trips and voltage drops

- Improve reliability of critical building systems

This proactive approach supports stable operations and predictable maintenance budgets—an essential consideration for large or multi-tenant properties.

Financial and Energy Efficiency Advantages

Beyond safety and compliance, power factor correction delivers measurable financial benefits. Improved power factor reduces demand charges, lowers electrical losses, and enhances overall system efficiency.

For commercial and industrial properties, this often results in:

- Reduced utility bills

- Improved energy performance metrics

- Stronger alignment with sustainability goals

These advantages make power factor correction not only a technical necessity, but also a financially responsible decision.

The Importance of Correct Specification and Expertise

Not all correction capacitors are interchangeable. Improper sizing, poor-quality components, or inadequate temperature ratings can introduce harmonic issues or system instability.

Expert suppliers understand:

- Load profiles across different property types

- Harmonic considerations in modern electrical systems

- Long-term performance requirements in Canadian environments

This expertise ensures that correction solutions enhance system health rather than compromise it.

Intelligent Electrical Management for Modern Properties

Power factor correction capacitors may operate silently in the background, but their contribution to safety, compliance, and property maintenance is substantial. For Canadian property owners and facility managers, investing in high-quality Power Factor Correction Capacitors in Canada is a strategic decision that protects infrastructure, reduces risk, and improves operational efficiency.

As electrical demands grow and standards tighten, intelligent power management is no longer optional—it is essential.

Frequently Asked Questions

What is power factor correction?

Power factor correction improves the efficiency of electrical systems by reducing reactive power and optimising current flow.

Why is power factor important for property safety?

Poor power factor increases heat and electrical stress, raising the risk of equipment failure and fire hazards.

Are power factor correction capacitors required in Canada?

While not always mandatory, utilities and codes strongly encourage correction to avoid penalties and inefficiencies.

How do correction capacitors reduce energy costs?

They lower demand charges, reduce losses, and improve overall electrical efficiency.

Can incorrect capacitor sizing cause problems?

Yes. Improperly specified capacitors can introduce harmonics or destabilise the electrical system.

How often should power factor correction systems be reviewed?

Regular inspection is recommended, especially after major equipment changes or load increases.

Leave a Reply